Water/Methanol

Injection Install

Read the instructions that came with the WI

kit

Review well over 1 dozen Team ZR-1 emails

where I included more install images.

At this time you can trigger the WI

controller using the MAP output signal or the throttle position sensor (TPS)

Updated controller will also support the

output frequency of MAF.

Tank must be higher then where pump is

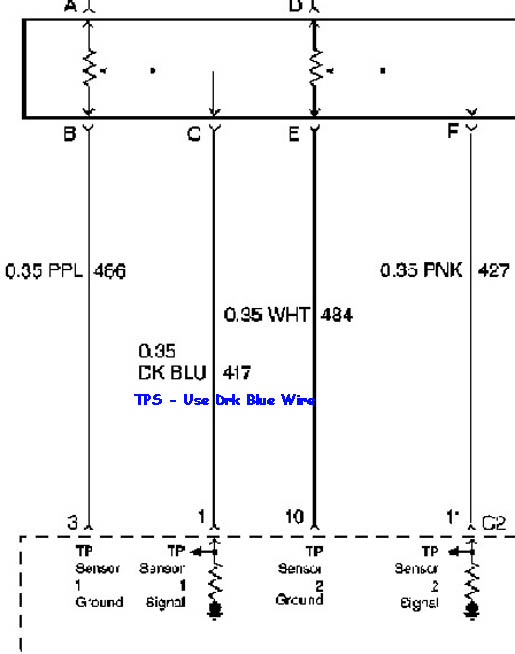

installed

The WI controller has its own built in

circuit breaker and controller draws very little current so you do not have to

connect to a switched source for there is not a free switched D/C in the engine

bay.

I added a main On/Off switch in driver area

but not required

WI pump is adjustable: (leave it at 140 PSI

default for most cases)

With screw fully clockwise = 140 PSI,

2 turns counter clockwise = 100 PSI and

4 total turns = 60 PSI

1. Remove 2 nuts holding WW tank

2. Disconnect wiring connector from low level fluid sensor (it faces firewall)

3. Lift WW tank up and unclip pump wiring connector and pop pump off tank

4. Take WW tank out of engine bay and install 90 degree hose fitting by drilling hole as shown in image

5. Use grommet into that hole and insert hose fitting, Use GOOP brand as a sealer around grommet and tank

6. Install WI pump below master brake (lower fender well ) What I did was mount the pump to a thin aluminum sheet and simply used double sided velcro so pump sticks to fenderwell or you could mount it to the A pillar frame support.

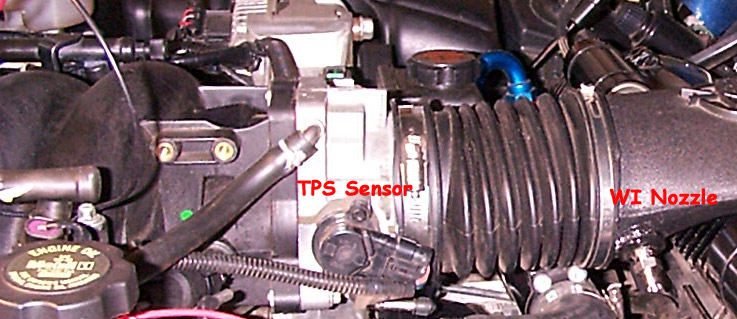

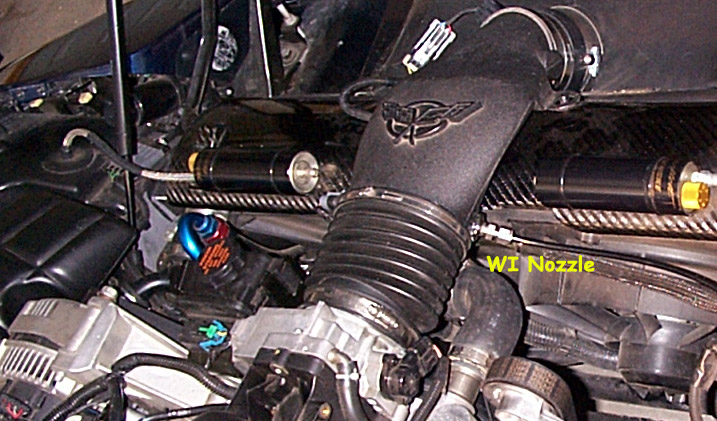

7. Install WI nozzle as shown close to throttlebody and use GOOP to make a good NO Airleak seal.

8. Run WI hose from nozzle to pump as shown (pump has flow arrows, connect to right outlet of pump)

9. Set WW tank back on and before bolting it down run a WI hose from inlet of pump to WW tank outlet you installed.

10. Mount WW controller as shown if you like, using WI drawing do all your wiring

11. Run 1 wire from TPS to controller and tap onto the drk blue TPS wire.

12. WI kit comes with a LED, I installed that in drivers area and

it goes to the wire from controller to pump so that LED only goes on when

controller is feeding the pump voltage

12. Reconnect WW pump and wiring connectors for pump and low level sensor, bolt WW tank in.

13. Refill WW tank with winter grade WW fluid which has 25 % methanol ( use that and not Alky brand)

14.

Set Switch A ( left one) of controller to

around 2 volts and set B switch to 4 volts, this allows the WI to come on

sooner and allows more carbon buildup to be cleaned out. After a few days

you then can raise switch A to a higher voltage so WI comes on at higher engine

loads

If WW fluid is not getting the air temps down then you need to purchase 99% methanol and mix a ratio to water that is best for the makeup of your engine.

Images of WI install :

With WW tank off notce the WI pump installed below

TPS - Tap onto the dark Blue wire

1. What are the benefits of Water/Methanol

injection?

Boost CoolerŪ Benefits (Gasoline):

1. Low cost - where else can you get up to 60HP.

2. More power than other means of detonation control.

3. Efficiency - leaner air fuel ratio can be utilized for normal operation.

4. Greatly increases air charge densities for huge horsepower increases.

Boost Cooler Benefits (Diesel):

1. Greatly reduced EGTs.

Decreases of 250 degrees F are common using a 50/50% Methanol /Water mix. This

prevents the usual problems associated with high exhaust car temperatures -

rings sticking, holed pistons, etc.

2. Low cost power - where else can you get 70-100 HP for approximately $400

along with reduced EGT's.

3. Greatly increased air charge densities - 3-5 psig boost increases are

common.

4. Great for towing - more power/cooler EGT's to haul

the heaviest loads.

2. Do I need an Intercooler

with Water/Methanol injection?

Up to approximately 20 psi

boost, water/methanol injection will provide all the density

increase/detonation control needed in most applications. Of course, Intercooling and water/methanol injection would provide

even greater benefits especially beyond 20 psi boost.

Most air-to-air intercoolers are only 50-65% efficient. That means for example,

that with 11psi boost and its 120°f air charge temperature increase, an

intercooler reduces the air charge temperature only 60 degrees. Also, an

intercooler will reduce boost 2 - 4 psi. on average.

3. Why not use a windshield

washer pump?

Water/Methanol must be injected at above 50psi

to properly atomize. Lower than 50psi causes greatly reduced air charge cooling

as the result of larger droplets and their reduced total surface area.

4. Why methanol?

Methanol is a high octane fuel that is extremely

resistant to detonation with an excellent cost/benefit ratio. ($1.50 - $2.00 per gallon.) Its high latent heat of

vaporization also makes it an excellent air charge cooler which means a denser

mixture and more horsepower. Because of these facts, it is a better anti-detonant than ethanol or iso-propanol

although they will work in a pinch. It has however only about 60% of the energy

content of gasoline by volume so about twice as much is used to make similar

power if used as a straight fuel. It is extremely toxic and should be handled

with rubber gloves in well ventilated areas only. Care should be taken to avoid

skin contact.

5. How much Water/Methanol?

To prevent detonation, the ratio of Water/Methanol

to gasoline is roughly 1 to 5 in gasoline applications- 1 to 4 in diesel. In

practice, you give it as much water / methanol as it takes to eliminate

detonation without quenching combustion. The amount depends on the onset RPM of

injection, the octane of the gasoline, fuel/air ratio, cylinder head type, even

the weather conditions. Your engine is actually pretty tolerant of extra water

vapor, you will know it's too much when the engine misses and loses power.

6. Where can I purchase

Methanol?

Methanol can generally be purchased where racing

fuels are sold. Also, most gas line dryers like "Heat" are simply

Methanol. Suppliers of industrial chemicals can also supply Methanol usually at

a higher price than fuel suppliers. If all else fails, most windshield washer

fluids are up to 40% Methanol and 58% water. Methanol can be purchased on the

web at www.worldwideracingfuels.com and hiperfuels.com.

7. How long will a tank (2 qts.) last?

In high boost/high horsepower application, a

full blast 1/4 mile run will utilize as much as 1/8 tank. A larger tank should

be considered if over 9psi boost is utilized in road racing where a tank can be

used in as few as 6 - 2 mile/ full tilt laps. Under normal street use in a 400

HP Mustang, a tank usually lasts about 500 miles. Two reservoirs can be used

for 1-gal total capacity if desired. Turbo diesels use more qty. and usually

utilize the existing windshield washer reservoir (over 4 qts.

in most cases) or the new 8-gal reservoir upgrade. More will always be used when

the system is first installed, less when the novelty wears off.

8. Can I use windshield washer

fluid?

Although most contain some glycol and detergent,

most windshield washer fluids are up to 50% alcohol (methanol, ethanol, isopropanol) and make an excellent Boost CoolerŪ. Try to

find one that indicates "contains methanol".

9. At what boost level do I

introduce Water/Methanol?

Centrifugal superchargers/large turbos: Generally, at 50% of peak boost the recommended

quantity should be introduced. Positive displacement superchargers/ fast

spooling turbos: injection should occur at or near

peak boost to avoid combustion quench since peak boost occurs so fast.

10. What ratio of

Water/Methanol is recommended?

A 50/50 ratio is recommended. This has been

demonstrated to be the best for charge/air cooling, excellent detonation

control, and controlling cylinder temperature. This includes diesel

applications where water conditions the combustion of the methanol so

combustion timing isn't affected.

11. Many recommend Denso

Iridium spark plugs in boosted applications. Will these work

also with water/methanol injection?

Denso Iridium spark plugs are highly recommended

with the Boost CoolerŪ. Iridiums, with their low

firing thresholds and intense spark, allow for larger quantities to be injected

sooner without misfiring. This allows for more cooling of the intake air. If

you have a misfiring problem, nine times out of ten, Iridiums

will clear it up.

12. Will water/methanol harm

my engine?

In theory, at recommended quantities, most of the mixture is evaporated before it hits the

combustion chamber. Also, injection only takes

place at high boost levels minimizing cylinder wash concerns. Engines that have

been torn down after two years of water/methanol usage have shown no wear

issues only clean combustion chambers. In fact, water/methanol reduces the

probability of engine destroying detonation. Think of it as an insurance policy

against detonation.

13. Can the Boost CoolerŪ be

applied to naturally aspirated and nitrous engines?

1.Naturally aspirated/high compression engines:

In this application, water/methanol injection

allows the use of pump fuel in all but the most extreme situations which

effects tremendous cost savings as well as horsepower increases due to air

density increase and realized timing potential. The system is activated by a

throttle switch so that injection takes place only during high engine loads

when needed.

2. NOS engines: with NOS, water/methanol

injection allows the use of full timing even with large (250HP+) quantities.

Injection is controlled by the same means that controls NOS injection.

3. Naturally aspirated/stock compression: With

naturally aspirated engines with less than 10:1 compression, water/methanol is

used typically in warm climates to get the intake temps back to 60°f. Benefits

include: 10-15 HP increases from air density increases and full timing, Increased gas mileage, and carbon free combustion chambers.

Activation is by a throttle switch adjusted for onset engine load. With this

application, the nozzle is sized so that no more than 10% of total fuel

consumption at peak flywheel HP is injected.

14. Why is Water/Methanol

injection so effective on Diesels?

Unlike gasoline engines, the power in a turbo

diesel is largely a function of fuel. The problem with continually adding fuel

is that you reach a point where the exhaust gas temperatures become prohibitive

(over 1500 degrees F). A 50/50% Methanol/Water mix will decrease EGT's approximately 250°+ while increasing power 70-100HP.

Power is increased through:

a. Intake charge cooling - Water/methanol will

lower air charge temps over 200°f in this application.

b. Methanol - this acts as a fuel as well as cooling

the intake charge.

Where else can you get this kind of power with

cooler EGT's!

15. Is this technology new

with Turbo Diesel?

Water/methanol injection has been used

extensively for years in high performance truck/tractor pullers. With the

elevated boost levels required for peak power, water/methanol is a common means

of cooling the intake charge and reducing exhaust gas temps. Also, truckers

have used water injection for years to increase fuel mileage.