Teammate

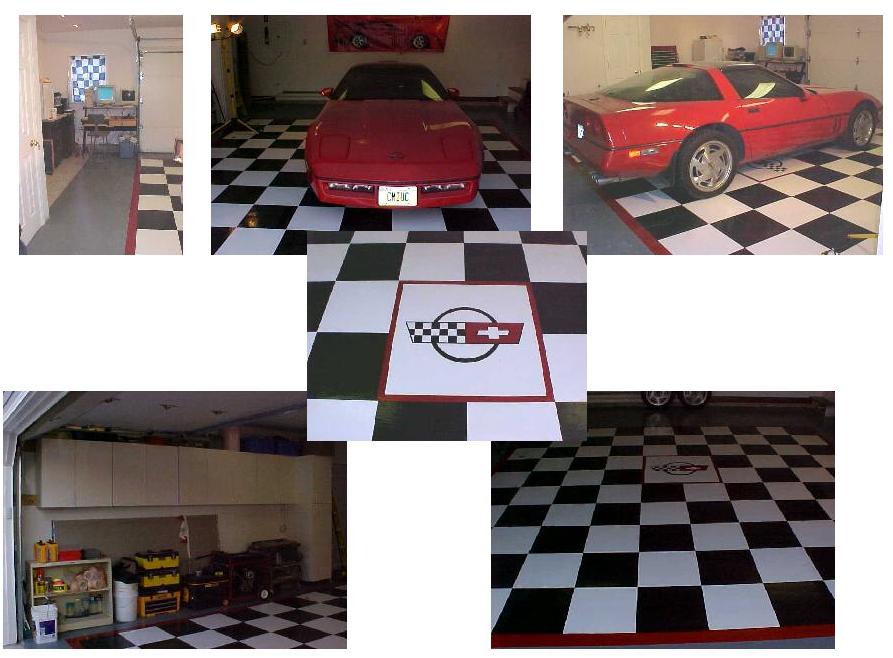

Al gives his í88 the floor it deserves

![]()

Last

year we finished our Butlers Cottage Garage we built the previous year.

Carolyn now refers to it as ďALís Toy BoxĒ (Hum) but something

was missing.

The

floor wasnít painted. I didnít think this was going to be a big deal, as I

was going to paint it a Navy Gray. Then

as I looked into painting cement floors, I found out that ALL cement paint or

stain wears off and requires to be repainted every couple of years, and the

choice in colors was very limited. By this time in the project, I was a little

frustrated and looking at using Grey, White and Black tiles on the floor.

The

color choices were OK, but I really wasnít looking forward to doing a tile

job in the garage. (Little did I know where this was going).

Then

I learned about several 2-part epoxy products out on the market. Sounded

great, but I didnít like there color options at all. Then I learned about

Rustoleumís commercial 9100 series 2 part epoxy paint system and they had

ALL the colors that I was looking for: Grey, Black, White and Red (the project

has now expanded considerable).

Well,

as time passed, the painted floor grew to a Navy Grey floor, with an 18 x 18

Ft White & Black checkerboard with a 6 inch Red boarder, with a 4 Ft.

Corvette logo in the middle (Hum, wonder if I need GMs approval for that

one??).

Itís

now early December, and the temperature has started to drop. Rustoleumís

customer service department to the rescue!!

They had a low temperature activator (40-60 degrees).

After

numerous calls to their customer service department I had a battle plan (at

least I thought I did).

I

now needed to determine how much paint I needed?

What

makes this project interesting is there is a time limit before you can put a

second coat on, and a cure time. Should you wish to place a second coat on or

another color on top of the 1st, you must do it before the epoxy

cure Ė Thatís an 18-24 Hrs window depending on Temp.). Otherwise, you have

to use a commercial sander to rough up the surface before applying an

additional coat of epoxy paint.

As

time was a premium, I decided to paint the floor in stages.

But before we talk about painting we canít forget ALL the prep work

that is required. The cement must be clean, clean, clean.

If

you think it is clean, clean it againÖÖ I used a commercial acid to etch

the cement per Rustoleumís prep requirements, and used a heavy-duty oil

degreaser on the few oil spots that I did have. It took two of us 6 Hrs to get

the cement etched and cleaned. Now off to HD we go for all the miscellaneous

supplies - rubber gloves, 1 doz. paint rollers, 3 mixing rods, 12 disposable

brushes & mixing containers, 10 rolls of GOOD masking tape, and a

wallpaper roller.

The clock has started ticking Ė we are on a mission.

I

taped out the 18 Ĺ Ft x 18 Ĺ Ft square. All the large stuff in the garage I

didnít want to move was placed in that area. (Wrong move, was a pain in the

but) and painted the 1st Grey coat. As I was painting up to where

the garage door comes down, I left the door open ~ an inch over night so the

door wouldnít stick to the floor. (Boy, that was a mistake). In the morning,

the Grey floor looked good, but needed a second coat. However, all the bugs in

the world and a lot of dust and leaves managed to blow in under the door. Have

you ever seen a lady bug that crawled across the paint and left little trails

behind them. Well these little suckers didnít get too far, but they were

encapsulated in the epoxy paint and were now a bump in the floor. Sooooo, out

came the palm sander and I sanded the entire area Ė Thatís after I cut the

lady bugs out of the epoxy paint. Several hours later I was ready for the

second coat of Grey. The 2nd gray coat went down and it looked

good. The following day it was time to look at doing the checkerboard.

All the junk that was in the middle of the floor could now be placed

along the walls. So up came the old masking tape and down went the tape to

outline Red boarder around the checkerboard. Two coats of Red epoxy and two

days latter it was finished (looks great).

Now

it was time to tackle the actual white & black checkerboard. So up came

the Red masking tape. In an effort to save time, I decided to paint the entire

center section with two coats of white epoxy paint and then overpaint it with

Black epoxy. At this point I had used a chalk line to determine where all the

lines were going to go, but that didnít work out as they just disappeared if

you walked on them, So off came the chalk lines. I started out with 1-foot

squares. After having taped the entire floor (Thatís 4-5 Hrs) and looking at

it from a distance, it looked too busy and didnít look good at all. So up

came all the masking tape. I then changed to 2 Ft x 2 Ft painted squares.

Another 5 Hrs passed and all the black squares were masked and ready for

paint.

(

It is extremely important to note at this stage in the project that the epoxy

floor be clean,clean,clean at this point in the process, so the masking tape

sticks to the floor (( Thatís what the wall paper roller is for)). Otherwise

the Black epoxy paint will migrate under the masking tape. And by the way,

there isnít any way to remove it once this has happened)

As

I started to paint the black squares, it became readily apparent one could

paint the wrong square very easily. So, I stopped painting, and placed a piece

of black tape in each square that was to be painted black.

The

next two days were uneventful painting the black squares. The checkerboard was

now complete. ( Looking Better!!)

Itís

now mid December and the cement floor is starting to get cold, and the floor

must maintain a temperature between 40-60 degree otherwise the epoxy will not

cure. The gas wasnít hooked up to the radiant heating system as yet,

however, if I turned on the circulation pumps the floor maintained a

temperature of 45-50 degrees throughout the entire process.

The

next week was spent painting the C4 Corvette logo.

The entire 4 x 4 Ft areas was masked with masking tape, and the circle

of the C4 emblem was cut out and ready for the Black epoxy. Then it was on to

the wings, individual black boxes and then the smaller bow tie emblem (Red

with a ľ Inch Black boarder). Although this was a small area to paint, it

took a lot of time to mask and cut out each section of the logo.

Now

that itís finished it looks GREAT!! Better than any car dealer show rooms.

Itís very easy to clean the dust, dirt and oil spills. But do I really want

to part a car on it??

As

for cost to do a garage, there are several commercial companies that will do a

standard 2-car garage with a Beige or Cream color speckle 2-part epoxy for

around $1000.

Or

you can upgrade your garage and spend around

~ $350 for the 2 part epoxy paint,

$30

for the acid and de-greaser, and ~ $150 for lots of masking tape, paint

rollers, brushes, etc

You

bet!! Would I do it again? Yup.

Now

that itís finished? Iíll be sending Rustoleumís Customer Service group

pictures of our combined effort. Their normal customers are paint thousands

and thousands of square feet of cement at a time and itís a single color.

Occasionally one may be painting two colors but there not adjoining colors.

Consequently, they were very interested about the process and the pitfalls of

registration with multiple colors. So,

now that weíve learned to use our digital camera during this process, Iíll

take another set and send them off to them. This spring or summer I plan on

doing the main garage however, I think we will stick to a single color, most

likely ďWhiteĒ.

Hum,

wonder if there is anything else to do to the garage?

The back wall looks awful blank.